However, our service includes much more. We control the entire production process, from advise to delivery and implementation. The possibilities vary from standard processes and sub-processes to custom-made produced products.

Bestronics provides full support in the field of applications and use of micro-electronics. Our knowhow enables us to fulfill an advisory role in the initial stage of the production process. It applies to new products but also to improvement and adjustment of existing products. In close consultation we examine if standard components can be used or if development of special electronics is required. As a result, costs are transparent and can be reduced to a minimum.

The step from prototyping to actual production is not only well-founded, but efficient as well.

The same efficiency goes for the strong automation Bestronics applies, which results into a faster purchasing process and lower costs, as the purchasing process is bundled. The automation of Bestronics allows tracking and tracing of all incoming and outgoing components. Thanks to this automation, stock can always be kept to standard. Bestronics can provide the purchase of the entire components package. In addition, we give advice with regard to the use of alternative components.

We use a transparent calculation to make sure you as a customer know exactly the costs of components and production. However, input of your own specific components is possible as well.

After the design phase, Bestronics can develop a prototype that is accurately tested. Possible changes can be adjusted in the final design, before the actual serial production is started. It allows the product to be definitely tested in the market. In addition, the production method can be checked for efficiency.

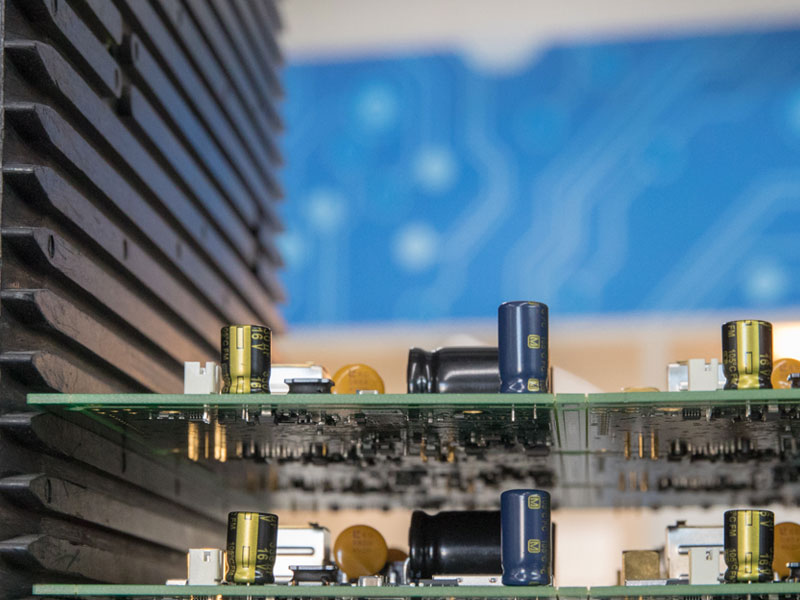

Bestronics BV has an extensive fleet with several production lines in her production area. In the production process the paste can be applied in the usual way, by using stencils. In addition, Bestronics has a Paste Jet machine, for more flexibility and prototyping. After applying the paste, the quality is checked by means of the paste inspection machines. The components are positioned with state of the art pick-and-place machines. After a final visual inspection, the chipped circuit boards can pass through the oven. For larger series, the Automatic Optical Inspection Machine can be used. Random checks take place in the X-ray.

Furthermore, Bestronics has a lead-free wave soldering machine for Through Hole production and a selective soldering machine.